The Sampling Central is a equipment with Turn Key concept for sampling process of raw materials. Use for analysis and release of the batch of material or product, it is usually installed in the production area or near the storage area of new lots.

The responsible for the sampling process should be in the case with the lab coat, mask and sterile gloves, and when this collection process is applied to a sampling station, it will provide protection ISO 5. The Flow of Protection prevents the dissemination of the material by environment, as well as the inhalation of the raw material by the operator.

“The Reintech Sampling Center has two sets of lighting in its current flow: one set of luminaires Tear Drop Light with LED lamps and the other with the yellow colors, which are used in processes where the product is photosensitive. The scope of a data set is an independent task and the choice of an example already existing in the sampling area tells us Eng. Bruna Rodrigues, responsible for the first REINTECH equipment exportation.

The Sampling Central provides a greater capacity of processing than cabins of laminar flow class II B2, increase productivity without compromising process strength and operator safety.

A CAM TK avoids cross-contamination in the processes and guarantees a depressurising of 10 to 15% of the total flow by environment. REINTECH presents a unique technique of negative plenum, which prevents air from being blown without through the HEPA filter.

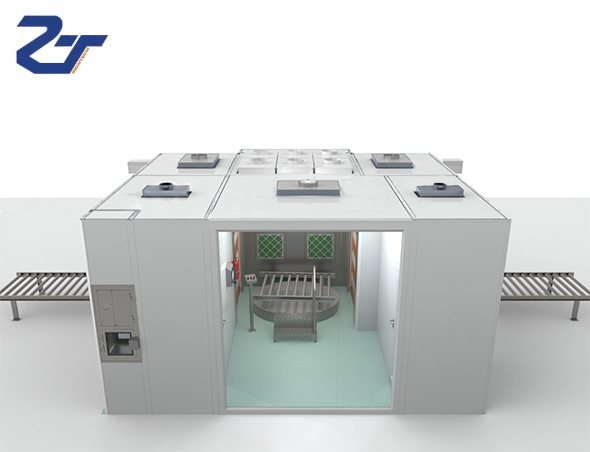

All about INOX AISI 304 or painted sheet the equipment is form by: Two Airlock of Materials, one Airlock of People and a Sampling Room with perforated table for the air flow. At the new CAM TK video from REINTECH channel you can see the flow of people and the flow of materials within the controlled environment where the entire process is monitored by the IHM and Industrial PLC.

“All tests made by Reintech’s for Sampling Central and Booths follow straight the applicable standards such as ANVISA, SBCC, NBR, NR10, AMCA used in equipment with traceability and their measurements. These tests are carried in two stages: in our factory before shipment (FAT) and after assembly in place (SAT), we repeat all tests to guarantee its perfect operation. We also provide all protocols for performing these tests. The FAT and SAT protocols of the equipment are advance shipped for comments and customer knowledge. This documentation is delivered together with the equipment Data book, with an electronic copy in our company for customer safety. ” Marco Aurelio, REINTECH’s engineer

The REINTECH Sampling Central has its special mode ATEX anti-explosion design options, with or without air recirculation. A microbiological, physical-chemical or unit dose analysis of the sample have to be done under a professional qualificated and supervision.